Basic Info.

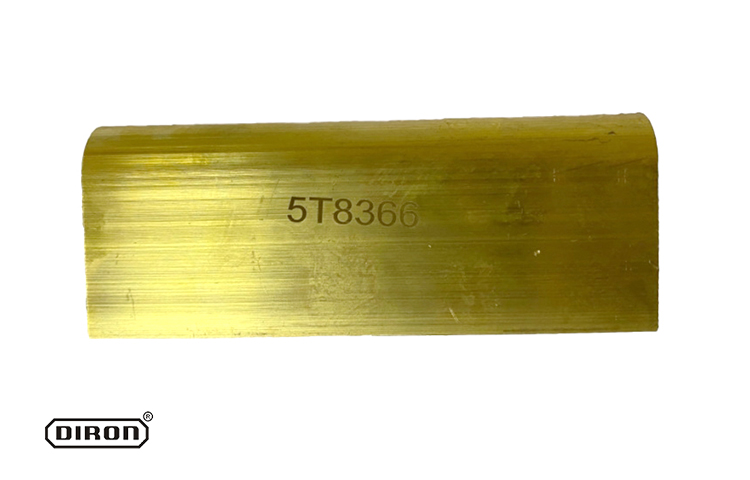

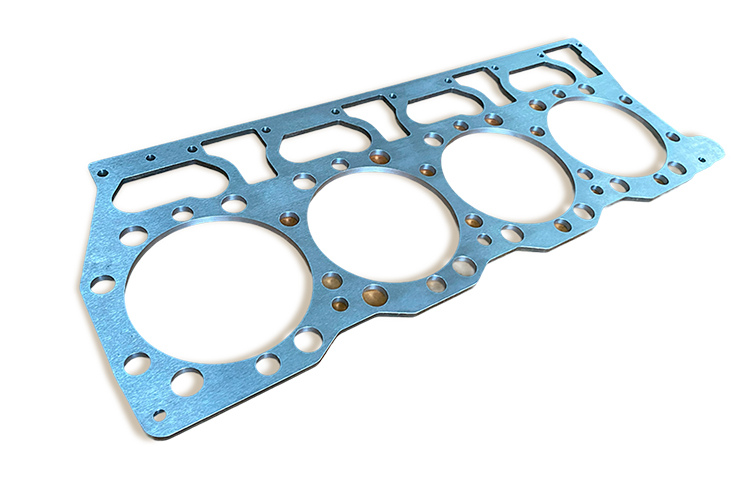

| Part no. | Bronze Strip Wear 5T8366 | Material | Iron |

| Type | Bronze Strip Wear | Weight | 1.37kg |

| Model | 12, 12G, 14E, 140G, 160G | Transport Package | Wooden Box |

| Trademark | DIRON | Origin | Luoyang City |

| HS Code | 84099991 | Production Capacity | 5000PCS/Year |

Product Details

- Item Model:Bronze Strip Wear 5T8366

- Date First Listed:2024/11/29

- Manufacturer:Diron Parts

Product Description

- Part Number:Bronze Strip Wear 5T8366

- Part Type:Bronze Strip Wear

- Compatible Equipment:Motor Grader for Caterpillar

Bronze Strip Wear is used in Motor Graders and other heavy machinery to reduce friction, minimize wear, and enhance the durability of critical components. Due to its self-lubricating properties, corrosion resistance, and excellent wear performance, bronze wear strips are applied in areas where smooth movement and precision are essential.

Key Applications of Bronze Strip Wear:

1. Moldboard Slide Rails:

- Purpose: Installed between the moldboard (grader blade) and the supporting frame to reduce friction during the lateral movement of the moldboard.

- Benefit: Ensures smooth, precise adjustments of the moldboard, critical for accurate grading and leveling.

2. Blade Guides and Supports:

- Purpose: Used in guiding systems where the blade moves up, down, or sideways, providing a wear-resistant interface.

- Benefit: Enhances blade positioning accuracy and reduces wear on both the blade and the guide structures.

3. Circle Drive Mechanism (Rotation System):

- Purpose: Located at the interface where the circular moldboard frame (circle) rotates, allowing the blade to pivot smoothly.

- Benefit: Ensures smooth rotation and reduces friction and wear in the circle drive, essential for changing blade angles efficiently.

4. Pivot Points and Bearings:

- Purpose: Used at pivot joints where components move relative to each other, such as the articulation point between the front and rear sections of the grader.

- Benefit: Reduces wear at pivot points, prolonging the life of bearings and joints while ensuring smooth articulation.

5. Lift Cylinder Mounts and Linkages:

- Purpose: Applied at the mounting points of hydraulic cylinders that control blade movement.

- Benefit: Minimizes wear and friction at the linkage points, ensuring consistent hydraulic performance and smooth blade operation.

6. Steering and Articulation Joints:

- Purpose: Used in areas where the grader’s frame or wheels articulate or steer, providing a wear-resistant surface for smooth operation.

- Benefit: Reduces friction at steering joints, improving maneuverability and reducing wear on moving parts.

Industries and Environments Where Bronze Strip Wear is Common:

- Road Construction and Maintenance: Ensures precision in leveling and grading tasks.

- Mining and Quarrying: Withstands harsh environments involving abrasive materials.

- Snow Removal: Provides corrosion resistance when exposed to salt and moisture.

- Agriculture and Land Preparation: Enhances durability in soil leveling and field preparation tasks.

Summary:

Bronze Strip Wear is widely applied in moldboard slide rails, blade guides, circle drives, pivot points, and hydraulic linkages within Motor Graders. Its ability to reduce friction, resist corrosion, and provide smooth movement makes it essential for extending the lifespan of components and ensuring efficient, precise grader operations across various industries.

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: FOB

Q4. How about your delivery time?

A: Generally, it will take 20 to 30 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from

Advatange

- Advatange One

Diron Parts Group Have Its Own Factory Ensure That We Offer Better Price For Customers. Besides, Diron Corporate With Some Reliable Principal Manufacturers, So Diron Also Supply Customer Other Quality Spare Parts.

- Advatange Two

With 18 Years Experience In Manufacturing And Exporting, Diron Has A Team Of Knowledgeable Engineers, Inspectors, And Skilled Workers

- Advatange Three

The Products Export To More Than 80 Countries In America, Europe, Africa, The Middle East And So On. Reliable Quality Parts Won Trust From Valued Customers.