Basic Info.

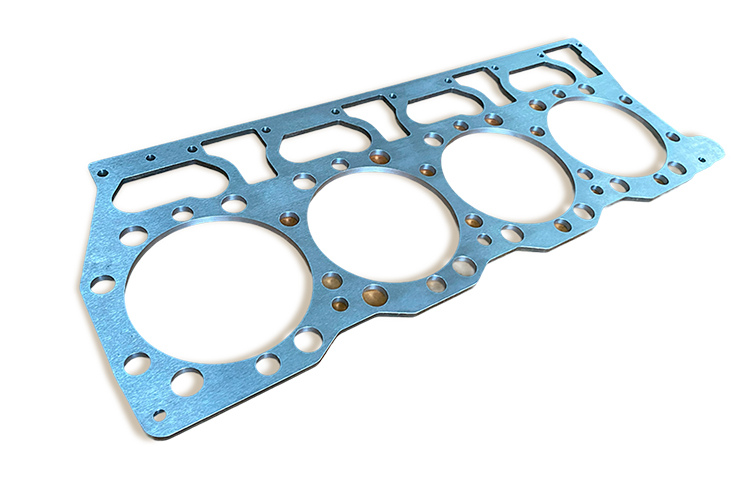

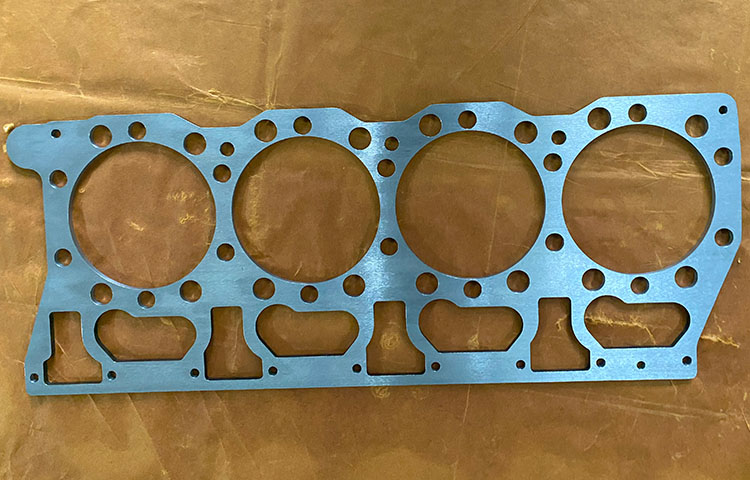

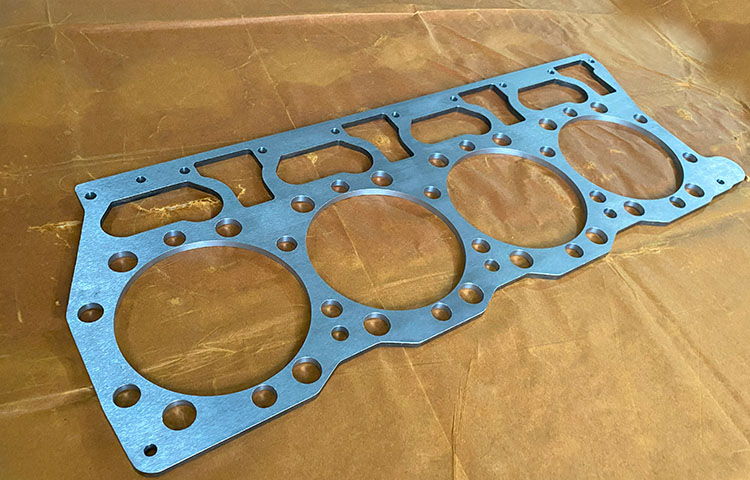

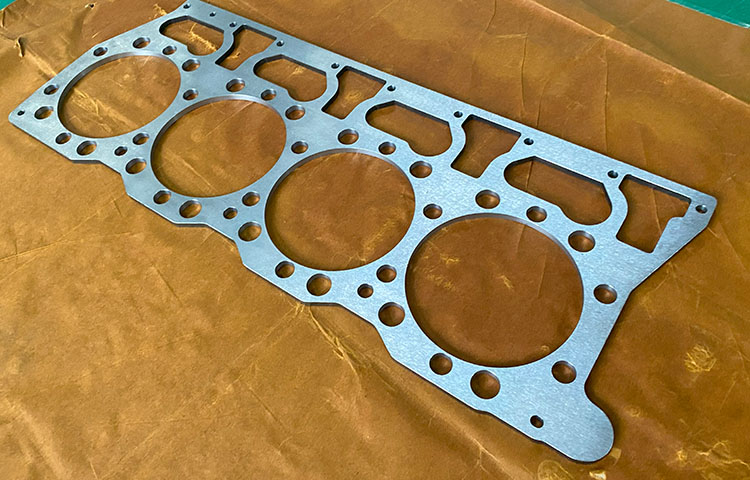

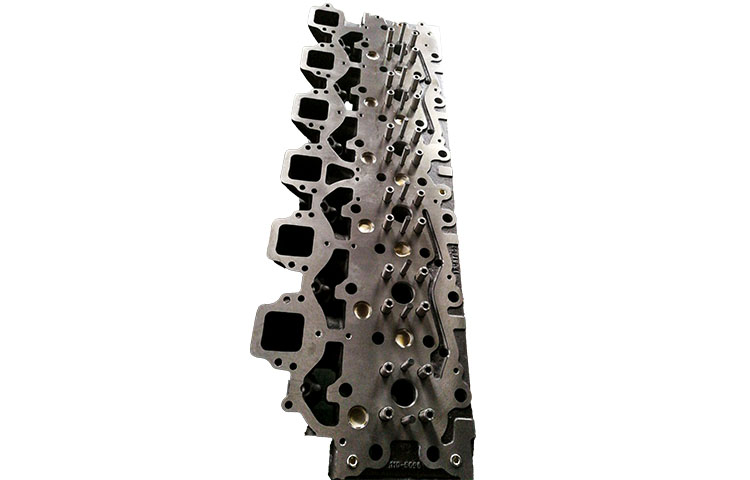

| Part no. | Block plate 614613 | Material | Iron |

| Type | Block plate | Weight | |

| Engine No. | 3408 | Transport Package | Wooden Box |

| Trademark | DIRON | Origin | Luoyang City |

| HS Code | 84099991 | Production Capacity | 5000PCS/Year |

Product Details

- Item Model: 614613

- Date First Listed:2024/11/18

- Manufacturer:Diron Parts

Product Description

- Part Number:Block plate 614613

- Part Type:Block plate

- Compatible Equipment:3408 Diesel Engine suit for Caterpillar Excavator

The Spacer Plate plays a crucial role in diesel engines, typically positioned between the cylinder block and the cylinder head or between other specific components. It is primarily used to adjust the clearance between parts or to enhance sealing, ensuring efficient and reliable engine operation.

Key Roles of the Spacer Plate in Diesel Engines:

1. Adjusting Cylinder Height or Compression Ratio:

- Compression Ratio Adjustment: By varying the thickness of the spacer plate, the combustion chamber’s volume at top dead center can be fine-tuned, thereby altering the compression ratio. Since diesel engines rely on high compression ratios for fuel ignition, precise control of this ratio is vital for optimal performance.

- Compatibility with Different Pistons or Connecting Rods: Spacer plates allow flexibility in accommodating different piston or connecting rod specifications, enabling adjustments to engine mechanical parameters.

2. Enhancing Sealing Performance:

- Sealing the Interface Between the Cylinder and Cylinder Head: Diesel engines operate under high pressure, and the spacer plate can provide additional sealing to prevent combustion gas leakage, ensuring airtightness.

- Sealing Coolant and Lubrication Passages: It helps prevent the leakage of coolant and lubricating oil or their mixing with combustion gases, thus improving engine reliability.

3. Vibration Damping and Heat Insulation:

- Vibration Absorption: The spacer plate can absorb some of the vibrations and shocks generated during engine operation, reducing stress on the cylinder head and cylinder block and enhancing durability.

- Heat Insulation: In certain applications, the spacer plate acts as a thermal barrier, minimizing heat transfer between the cylinder block and cylinder head, thereby optimizing thermal management.

4. Filling and Correction Functions:

- Compensating for Manufacturing Tolerances: Spacer plates can correct slight discrepancies in machining or manufacturing tolerances, ensuring a precise fit between the cylinder head and cylinder block.

- Filling Space Gaps: During engine repair or modification, spacer plates can fill gaps caused by wear or replacement of components.

Common Materials for Spacer Plates:

- Steel Plates: Known for their strength and durability, ideal for high-temperature, high-pressure environments.

- Aluminum Alloy: Lightweight with good heat dissipation, suitable for engines where reduced weight is essential.

- Composite Materials: Offering excellent heat insulation and vibration damping, used in specialized applications.

Importance of the Spacer Plate in Diesel Engines:

- Diesel engines operate under extreme conditions of high pressure and temperature, so spacer plates must have excellent heat resistance, pressure tolerance, and sealing capabilities.

- They influence key engine parameters such as power output and combustion efficiency, directly impacting the engine’s overall lifespan and reliability.

Conclusion:

In diesel engines, the spacer plate serves multiple critical functions, including adjustment, sealing, vibration damping, and heat insulation. It plays a vital role in fine-tuning engine parameters like the compression ratio and ensuring stable, efficient operation under demanding conditions.

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: FOB

Q4. How about your delivery time?

A: Generally, it will take 20 to 30 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from

Advatange

- Advatange One

Diron Parts Group Have Its Own Factory Ensure That We Offer Better Price For Customers. Besides, Diron Corporate With Some Reliable Principal Manufacturers, So Diron Also Supply Customer Other Quality Spare Parts.

- Advatange Two

With 18 Years Experience In Manufacturing And Exporting, Diron Has A Team Of Knowledgeable Engineers, Inspectors, And Skilled Workers

- Advatange Three

The Products Export To More Than 80 Countries In America, Europe, Africa, The Middle East And So On. Reliable Quality Parts Won Trust From Valued Customers.