Basic Info.

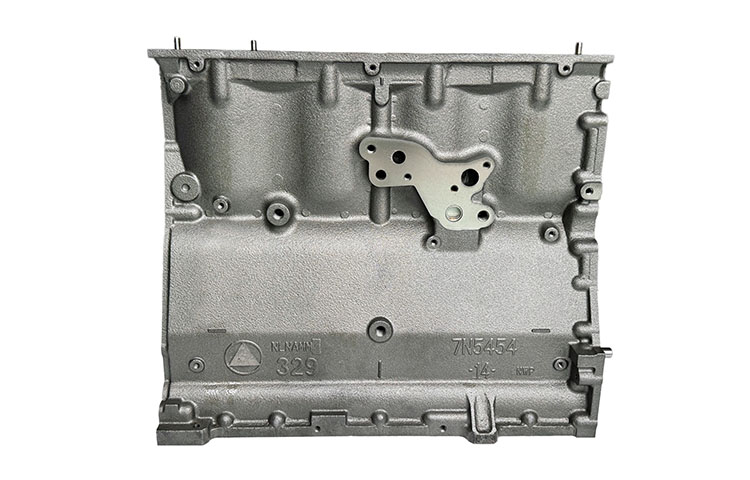

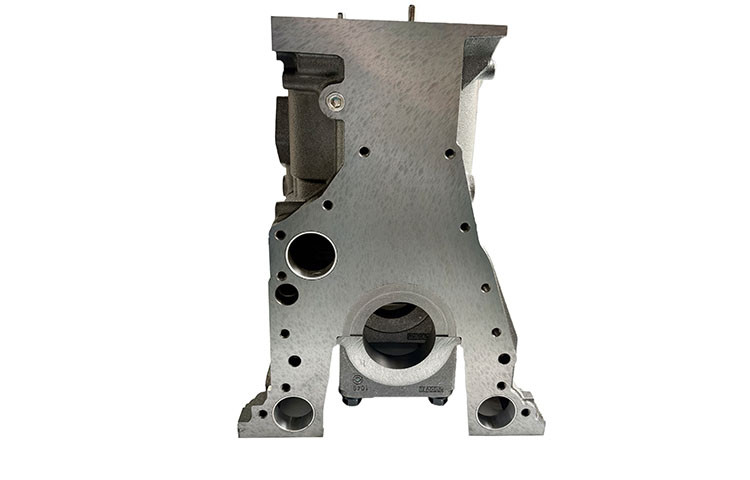

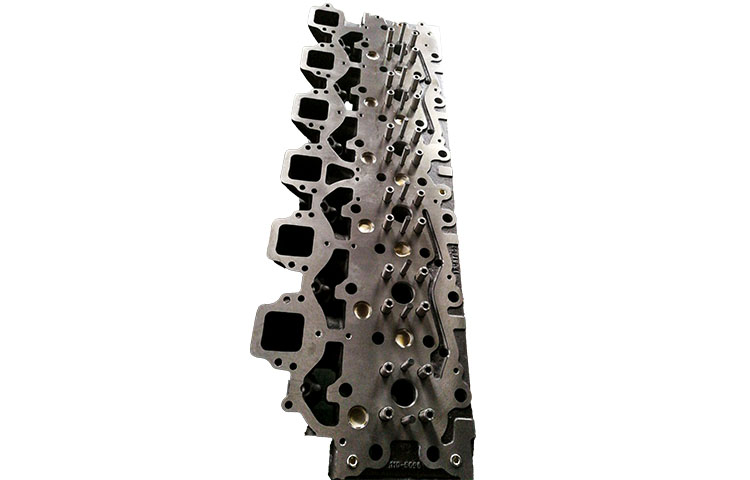

| Model NO. | 1N3574 | Material | Iron |

| Type | cylinder block | Part no. | 1N3574 |

| Engine No. | 3304 | Transport Package | Wooden Box |

| Trademark | DIRON | Origin | Luoyang City |

| HS Code | 84099991 | Production Capacity | 5000PCS/Year |

Product Details

- Item Model:1N3574

- Date First Listed:2024/11/1

- Manufacturer:Diron Parts

Product Description

- Part Number:1N3574

- Part Type:cylinder block

- Compatible Equipment:3304 Diesel Engine suitable for CAT Caterpillar

In diesel engines, the cylinder block plays a crucial role as the foundational structure and core component of the engine. It is responsible for supporting, housing, and ensuring the smooth operation of critical moving parts. Since diesel engines experience higher compression ratios and combustion pressures, the design and material selection of the cylinder block are particularly important.

Key Roles of the Cylinder Block in Diesel Engines:

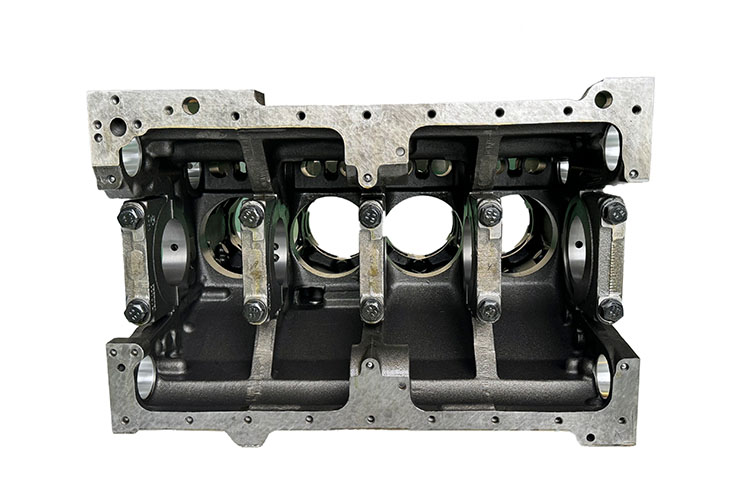

1. Housing and Supporting the Cylinder and Piston:

- Diesel engines rely on compressed air to ignite the fuel. The cylinder block provides a sturdy and precise space for the piston to move, withstanding the high temperatures and pressures of combustion.

- Pistons move rapidly in the cylinders, so the block must maintain shape stability and provide wear resistance.

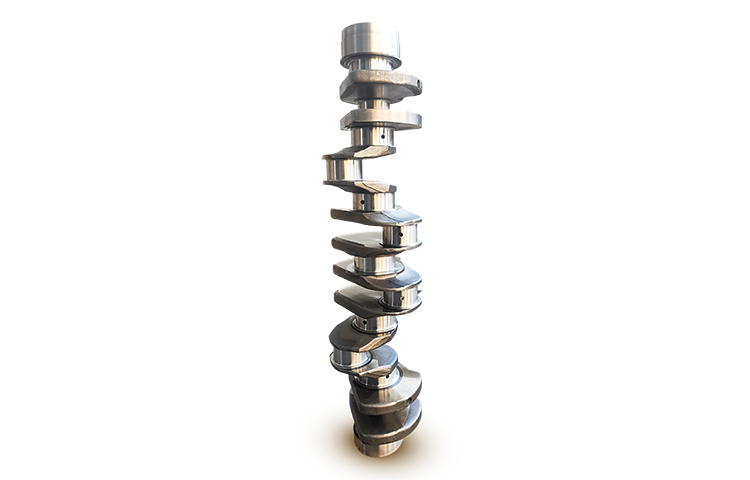

2. Supporting the Crankshaft and Connecting Rods:

- The crankshaft, located at the bottom of the cylinder block (crankcase), converts the piston’s linear motion into rotational motion. The cylinder block supports the crankshaft, ensuring its smooth rotation while withstanding the forces from the pistons.

- The connecting rods link the pistons to the crankshaft, and the block must absorb substantial mechanical loads.

3. Cooling and Heat Dissipation:

- Diesel engines generate significant heat during combustion. The cylinder block features internal cooling passages (water jackets) or oil passages to circulate coolant and dissipate heat, maintaining optimal operating temperatures and preventing overheating.

- Due to the high operating temperatures of diesel engines, an efficient cooling system is essential.

4. Lubrication System Channels:

- The cylinder block includes oil passages that distribute engine oil to critical parts such as the crankshaft, connecting rods, and pistons, reducing friction and wear.

- Given the high loads and pressures in diesel engines, the lubrication system must be highly effective to ensure long-term reliability.

5. Load Bearing and Vibration Damping:

- Diesel engines produce greater vibration and noise due to higher compression ratios and combustion pressures. The cylinder block must be designed with high rigidity and vibration-damping capabilities to ensure smooth operation and prolonged engine life.

Special Requirements for Cylinder Blocks in Diesel Engines:

Material Selection:

- Cast Iron (Gray Cast Iron or Ductile Iron): Offers excellent wear resistance, heat resistance, and rigidity, making it suitable for diesel engines that endure high temperatures and pressures.

- Aluminum Alloy (for high-performance diesel engines): Lighter but requires enhanced design to handle higher mechanical loads.

Enhanced Structural Rigidity:

- With compression ratios typically ranging from 16:1 to 22:1, the cylinder block must have high strength and rigidity to prevent deformation and cracking.

Efficient Heat Dissipation:

- Diesel combustion produces more heat, so the cooling system within the cylinder block is often more complex to ensure effective heat dissipation.

Conclusion:

In diesel engines, the cylinder block not only serves as the structural foundation for all engine components but also withstands extreme mechanical and thermal stresses. It plays a vital role in the engine’s stability, efficiency, and durability. The design of diesel engine cylinder blocks emphasizes high strength, rigidity, and efficient cooling to ensure reliable performance under demanding conditions.

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: FOB

Q4. How about your delivery time?

A: Generally, it will take 20 to 30 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from

Advatange

- Advatange One

Diron Parts Group Have Its Own Factory Ensure That We Offer Better Price For Customers. Besides, Diron Corporate With Some Reliable Principal Manufacturers, So Diron Also Supply Customer Other Quality Spare Parts.

- Advatange Two

With 18 Years Experience In Manufacturing And Exporting, Diron Has A Team Of Knowledgeable Engineers, Inspectors, And Skilled Workers

- Advatange Three

The Products Export To More Than 80 Countries In America, Europe, Africa, The Middle East And So On. Reliable Quality Parts Won Trust From Valued Customers.