Basic Info.

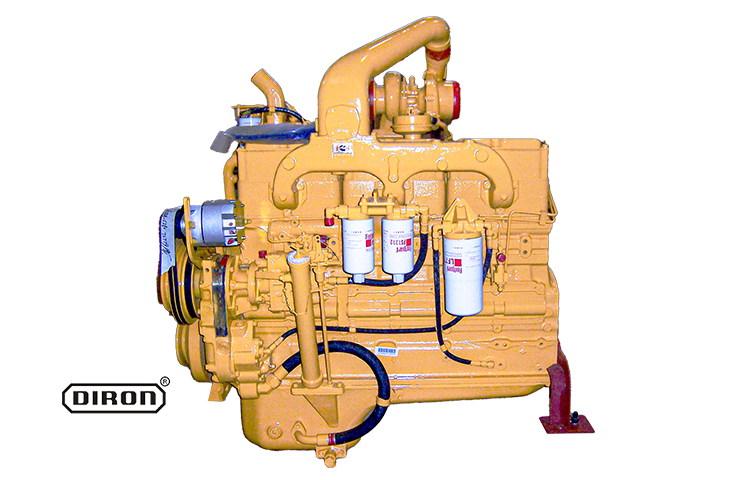

| Part no. | Block plate 6I4421 | Material | Iron |

|---|---|---|---|

| Type | Block plate | Weight | |

| Engine No. | C15 C18 3406E | Transport Package | Wooden Box |

| Trademark | DIRON | Origin | Luoyang City |

| HS Code | 84099991 | Production Capacity | 5000PCS/Year |

Product Details

- Item Model: 1106994

- Date First Listed:2024年11月19日

- Manufacturer:Diron Parts

Product Description

- Part Number:Block plate 6I4421

- Part Type:Block plate

- Compatible Equipment:C15 C18 3406E Diesel Engine suit for Caterpillar Excavator

In a diesel engine, a “Block Plate” typically refers to a metal plate used to cover or seal specific openings. Its primary function is to manage the internal flow of fluids (such as coolant or lubrication oil) or to simplify the design and manufacturing of the engine. Here are its roles and applications:

1. Primary Functions

(1) Sealing Function

Prevent Leakage: A Block Plate is used to seal reserved openings on the engine block or related components, preventing the leakage of coolant, lubrication oil, gases, or other substances.

Ensure Airtightness: Some Block Plates are designed to maintain airtightness in highpressure areas during engine operation.

(2) Ease of Installation or Maintenance

During engine manufacturing, openings or passages may be designed for machining or inspection. A Block Plate can seal these openings after the machining process is complete.

During maintenance or repair, the Block Plate can be removed to allow access to internal components.

(3) Fluid Management

Control Flow: Certain Block Plates guide or block the flow of coolant or lubrication oil within the engine, ensuring the fluids circulate along the designed pathways.

Separate Areas: In complex engine designs, a Block Plate can separate different chambers or regions to prevent fluid mixing.

2. Common Applications

Sealing Reserved Holes in the Engine Block: The engine block typically has passages or openings for manufacturing or inspection, which are sealed with a Block Plate during final assembly.

Cooling System Usage: Block Plates may appear in coolant passages to control the flow path or seal unused branches.

Lubrication System Management: Used to seal specific oil circuit openings, preventing leakage or misdirection of lubrication oil.

Modifications or Testing: During engine modifications or testing, Block Plates can temporarily seal certain components.

3. Material and Structure

Block Plates are typically made from:

Metal (e.g., steel, stainless steel, or aluminum): Resistant to high temperature and pressure, suitable for engine environments.

Designs with Sealing Gaskets: To enhance sealing effectiveness, Block Plates are often equipped with rubber or silicone gaskets.

4. Precautions

Installation Quality: Ensure that fastening bolts are tightened evenly during installation to prevent leakage caused by looseness.

Durability of Sealing Materials: Regularly inspect the gasket’s condition to ensure it is not aging or damaged.

Routine Maintenance: Especially in highload engine operations, the reliability of the Block Plate is crucial.

If you have a specific diesel engine model or scenario in mind, we can discuss its role and considerations further!

Information from cylinder head shop